5D CAD? From CAD Design to Finished Part

SPI SheetMetal Solutions help the Bader Group to achieve location-independent sheet metal production in a heterogeneous machine park.

Continuous growth, several manufacturing locations with centralised construction, heterogeneous machinery as well as the opening of a central cutting centre for southern Germany presented the Bader Group with a technical challenge. The IT developer SPI helped them to implement the best solution.

Since its founding in 1952, the Bader Group has become a specialist in the manufacture of machine enclosures, switch cabinets, and special housings. These days the Bader Group is a big player in sheet metal processing. With over 1,000 employees, it manufactures at four production sites in Germany as well as two more in Hungary and Romania Bader’s clients include industry giants from the mechanical engineering sector.

In 2016, Bader opened a new cutting centre at the company’s headquarters and founding location in Senden, Germany. It was well equipped with brand new automated punching and laser machines and a central raw material warehouse. “We eagerly went into operation but, unfortunately, programming with the OEM systems turned out to be a bottleneck,” recalls Tobias Höhnlein, Head of Industrial Engineering. “Existing CAD parts had to redesigned for production in different sites. It was clear that this could not remain a permanent state of affairs.”

In order to provide the required process information and control the various machines, Bader decided for SPI SheetMetal in conjunction with WiCAM’s PN4000 programming system. The company already has 19 SPI licenses and plans to purchase more in the near future.

Our goal was to be able to manufacture every product at every location. When we design parts here at the headquarters, the designer should not care whether the part will be manufactured in Germany or in Hungary. However, the different sites have different machines with different deduction values so production location is certainly not unimportant.

Cross-site Manufacturing Capability

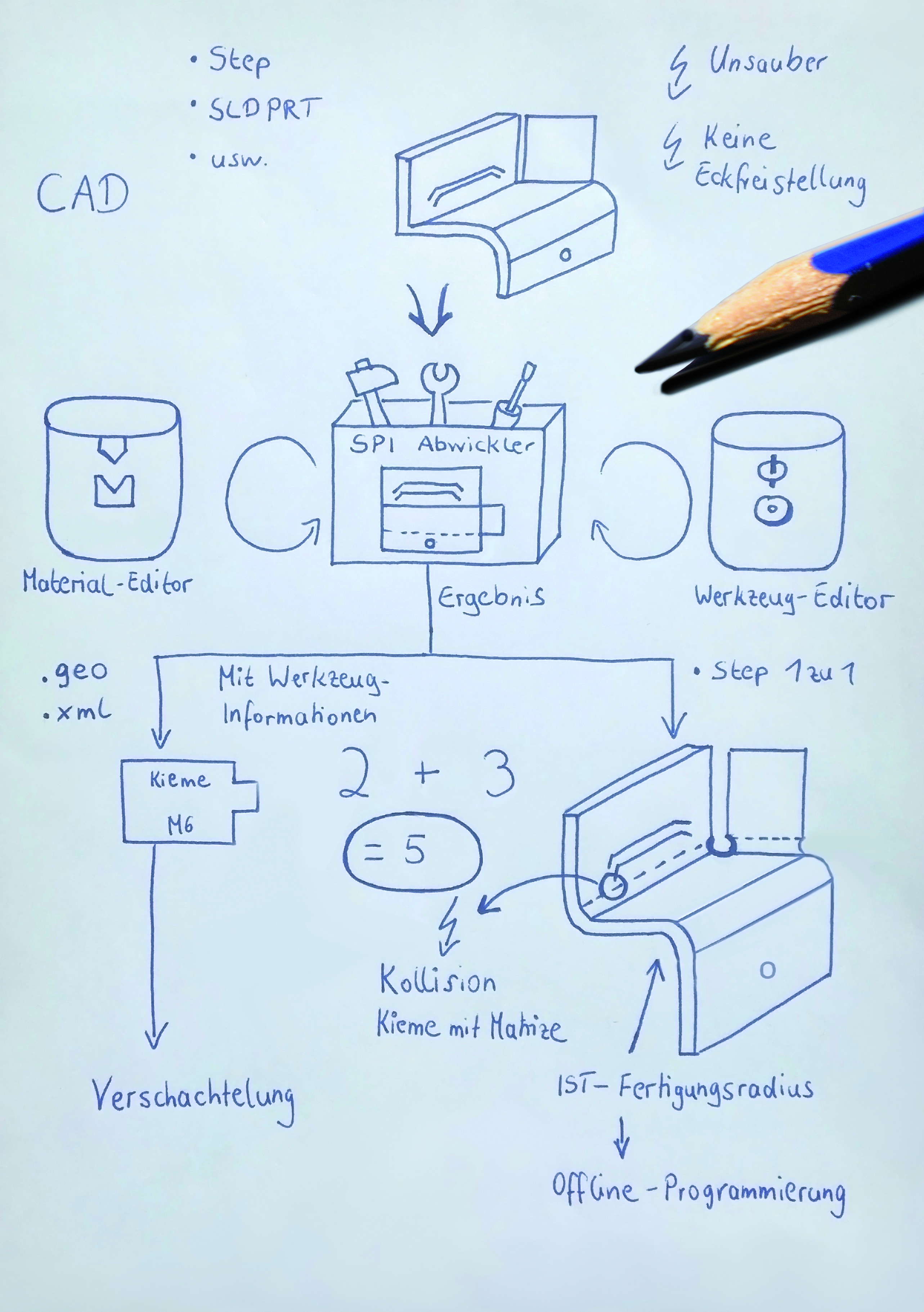

The SPI sheet metal unfolding software ensures that the CAD data is provided with cutting and machining data and transferred to the programming system as an XML file that includes all information relevant for the manufacturing process The SPI software also delivers GEO data that can be used in other Bader production sites without needing additional adjustments for the machines used there.

The next challenge turned out to be the heterogeneity of the machine park across the different production sites: it includes machines from Amada, EHT, Hämmerle, Salvagnini, and Trumpf. This challenge has now been overcome. Thanks to the editor that is integrated into the SPI solution and allows to manage and retrieve different material and bending tool combinations, it takes just the press of a button to create the necessary flat patterns with machine-specific deduction values for the various production sites.

“This way we receive the exact data we need for production at the respective location in a timely matter. Even if we do not yet know where we will manufacture during the design phase,” says Höhnlein.

An important further step for process automation is the introduction of the SPI solution for ensuring manufacturable reconstruction of parts that took place in the summer of 2018. Regardless of how a part has been constructed, even if it contains false internal radii, inaccurate reliefs, or bending lines, after analysing the data the SPI software will not only create a GEO or XML file but also a production-ready STEP file. This file includes all process information, correct reliefs, punching and stamping data. The result is a virtual prototype that shows the part as it would be manufactured, including the accurate production radii. Potential collisions in the bending process can be easily detected and fixed in time. The first manufactured part is faultless.

2 + 3 = 5

“In a sense, SPI delivers us 5D data,” jokes Tobias Höhnlein. “It includes the complete process information: first, the 2D pattern for laser cutting and punching, including tool information. And, at the same time, also a flawless 3D STEP file that is adapted to the respective machine for offline bend programming.”

The head of Industrial Engineering is thrilled: “We have brought strong and dynamic partners on board. We have optimized our processes and can continue to meet the increasing demands of our customers. In SPI we have found a development partner who understands our processes and turns their expertise into powerful software solutions.”

The Conclusion

What was the challenge?

The aim was to be able to manufacture any product at any location. However, each location has different machines with different deduction values.

What have you gained?

The SPI solution allows to manage and retrieve different material and bending tool combinations, making it easy to create the necessary flat patterns with machine-specific deduction values for the various production sites.

In a nutshell: the main advantage?

SPI gives us the complete process information: first, the 2D pattern for laser cutting and punching, including tool information. And, at the same time, also a flawless 3D STEP file that is adapted to the respective machine for offline bend programming.

What would you like others to know?

In SPI we have found a development partner who understands our processes and turns their expertise into powerful software solutions.

Reference as PDF

Here you can download the story, including all images.

Our Products

We help you to streamline your sheet metal process chain.

Our Offer

You would like to try it yourself? Contact us!

And More

Here you can find more references and stories.