SPI Manufacturing Interfaces

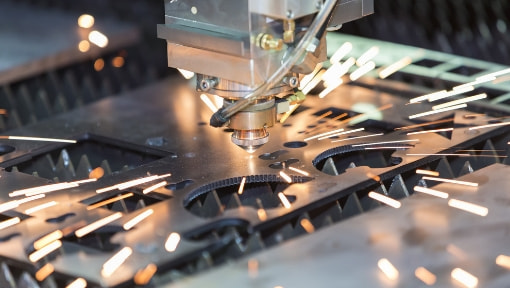

Data processing in the sheet metal process chain. Calculation basis and output formats.

How does the SPI software solution ensure data transfer within the process chain?

Data processing within the sheet metal process chain takes place according to the following paradigm:

- Definition of the calculation basis (Data Editor)

- Consideration of production-relevant parameters already during the design (the fault exclusion principle)

- Definition of output formats (unfolding destination)

- Calculation and output generation

- Data transfer to downstream programs for machine control

Use the SPI manufacturing interface to connect your processes. Here you can find some examples. And if you do not find a solution that works for your setup right away, talk to us. We will make it work.

SPI interfaces and output targets

The interface allows us to transfer all technical information, such as material and tooling data, directly to the machine control system. This means that the 3D models we create, including unfolding parameters, flow seamlessly into the manufacturing process.

Basis for calculation

The basis for the calculation of manufacturing-relevant process information is the data maintained in the SPI Data Editor. Thanks to the availability of the material and tool data, manufacturable bending radii and other factors are already considered in the design process. Our software calculates the unfolding and – depending on the available SPI interface – also provides output formats with all data relevant for manufacturing (DXF, GEO, STEP, WiCAM-XML).

The SPI SheetMetal Data Editor is our material and tool management system with which you maintain your technology data. Technology data is required for the correct unfold calculation as well as for transfer to the NC processing. First and foremost, these are bend deduction values or formulas, which are necessary for calculating the blank length. But also other elements which have an influence on the bending process, such as materials, sheet thickness or tools, are managed with the editor.

SPI SheetMetal offers several ways to import data on which to base these calculations.

The software supports various calculation methods for determining bend shortening, from own formulas to empirically determined measurements.

Measurements

Measurements allow for a more accurate representation of the dynamic bending process than formulas. A precise unfolding of a sheet metal part requires a sufficient amount of available deduction values. If no measurement is found for calculating a bend, it will be interpolated.

Formulas

Formulas enable the computation of the shortening factors for the input parameters (sheet thickness, opening angle, bend radius) and thus make the flat pattern calculation possible. Formulas can be set for:

- a material,

- a material and a machine,

- for a material and a combination of pistons and dies.

The SPI software evaluates the corresponding formula when calculating the flat pattern of a sheet metal part.

The output principle

The unfolding that is generated is compatible with the machines used in the process chain. You set the desired unfold destination and generate the corresponding file(s) in the format:

- DXF

- GEO

- STEP

- WiCAM-XML

This data can be directly processed with the leading NC programs.

Data transfer to NC programs

The intelligent networking of production systems, processes, and people is an essential feature of the sheet metal process chain. We understand these demands and accompany you in your environment, in your IT landscape, within your process chain, and help you to ensure seamless processes from the idea to the finished product.

Find our exemplary solutions for your machine environment here.

Supported controllers / CAM systems

We support the following controllers and NC programs with the corresponding output formats:

- TruTops Classic

- TruTops Boost

- PN4000

- BySoft CAM

- POS 3000

- Bysoft 7

- CADMAN L

- CADMAN B

- Delem

- Cybelec