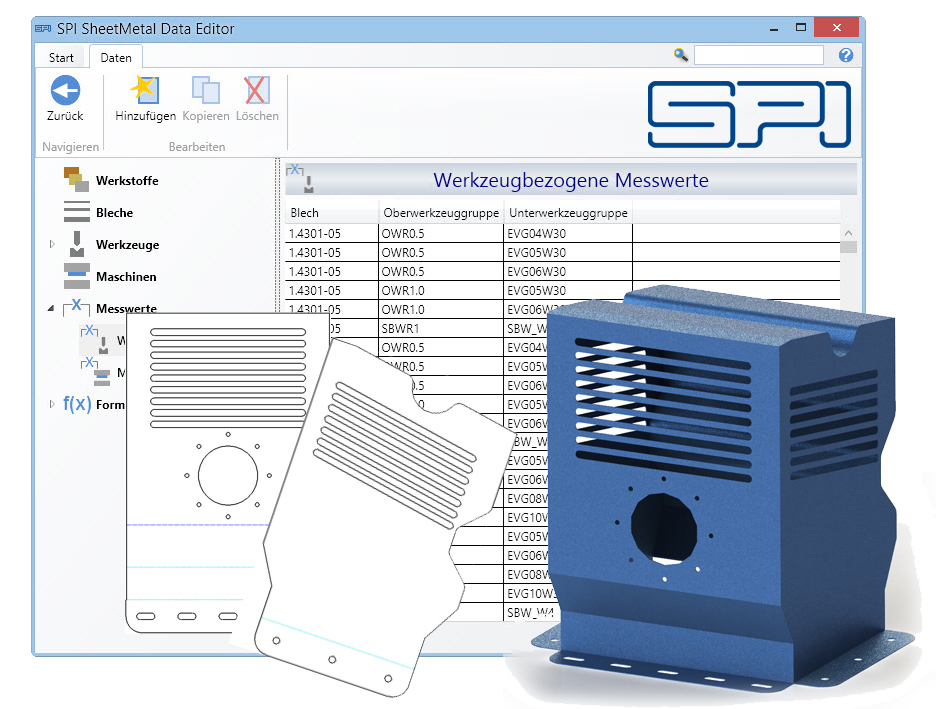

Data Editor

How to create a design that considers material properties, machines, and tools.

Precise, error-free, cost-effective, and fast.

What are the benefits of SPI Data Editor?

Know defining conditions, organize recurring parameters, efficiently maintain the relevant data, exclude possible faults at an early stage, and easily manage costs and time-frames:

in the SPI Data Editor, the values used for calculating sheet metal unfolding are clearly and conveniently organized in relation to materials, tool properties, and machines. This way, they are taken into account already during the design phase and help to ensure a manufacturable unfolding.

The SPI Data Editor is part of the SPI SheetMetal solution that helps you to maintain your technology data. They are required for the unfolding calculation as well as for the transfer to NC processing.

This entails bend deduction values or formulas, which are necessary for calculating the flat pattern. Also manufacturing materials, sheet thickness, and tools that have an impact on the bending process are managed with the help of the Data Editor.

The stored measurements and formulas are considered already during design to guarantee a manufacturing-ready unfolding. With this concept, SPI software ensures continuity of the production process from the design of sheet metal parts and assemblies to unfolding and subsequent transfer to NC programs for manufacturing control.

Measurements

Measurements allow for a more accurate representation of the dynamic bending process than formulas.

If a sufficient number of empirically determined shortening values are available, the software can create a precise unfolding of the sheet metal part. If such values are not found for calculating a bend, it is interpolated from adjacent measurements. The number of measurements thus has an impact on the accuracy of the unfolding. The measured values have to be determined for each metal sheet for which an unfolding is created, and they have to be stored in the technology database.

The measurements are stored in tabular format and can be assigned to either a machine or a tool. SPI SheetMetal software accesses the corresponding values, depending on the assigned property.

For machine-related measurements, you can define a table for each machine and each metal sheet that contains shortening attributes for opening angles and bending radii. In addition, you can add a table with deduction values for offsets and a table with manufacturing radii for opening angles.

With this information, the software can calculate the flat pattern on the basis of the manufacturing radius as opposed to the bending radius from the design. Alternatively, the shortening value can be calculated on the basis of formulas, the K-factor, or tabular empirical values.

When working with assemblies, a command allows to simultaneously unfold all sheet metal parts of an assembly. Material data and unfolding parameters can be assigned either to individual parts or to all parts of the current assembly.

Formulas

Formulas make it possible to determine the deduction values for the input parameters (sheet thickness, opening angle, bend radius) and thus to calculate the unfolding of the sheet metal part.

With the help of SPI’s material and tool management program, the Data Editor, you can define your own formulas for calculating deduction value as well as formulas for calculating the K-Factor. Special formulas can set for calculating joggle joints and manufacturing radii.

The bending process is not the same for sheets with different steel grades. This means that formulas for the material, and possibly also for the machine or tools used must be adapted. Formulas can be set for:

- a material,

- a material and a machine,

- for a material and a combination of pistons and dies.

The SPI software the corresponding formula is evaluated when calculating the unfolding of a sheet metal part.

Frequently asked questions

Is it possible to work without the Data Editor?

Of course. But the results are not particularly useful. The way in which the bend deduction is determined is defined in the software by setting appropriate parameters. A function allows direct import from machine databases. This allows you to develop flat patterns that can be directly passed on in the process chain.

Can I define favourites?

The SPI software allows you to set your preferred bending tools. When assigning a material to a component or an assembly, they are automatically called up and included in the unfolding calculation.

Which import formats are available?

Which export formats are available?

SPI software provides numerous export formats that ensure continuity within the process chain. The unfolding, together with all production-relevant information, is directly transfered to CAM applications for punching/nibbling, laser cutting, and bending.

Manufacturable unfolding

The sheet metal plate undergoes significant changes during the forming process. Therefore, the required manufacturing dimensions of a plate differ from a purely geometrical unfolding. SPI software calculates the shortening in the bending zones based on the material and tool properties that are stored in the Data Editor.

Various calculation methods are available for determining the technology data. Depending on the application, you can choose between DIN formula, K-factor formula, own formula, or empirically determined values.

The deduction values can be defined differently for each bend. Our software supplies a manufacturable flat pattern which can be directly transferred to laser, punching, or bending programs and can be used for machine control with barely any effort.

The SPI Data Editor supports you from an early stage of the manufacturing process: in the design and the transition between design and processing. With the help of the software, material data can also be attached to imported models (DWG, SAT, IGES). Sheet thickness is determined automatically, making it possible to create a correct flat pattern despite inaccuracies in the model.